Vitamin Bottles

Frequently Asked Questions About

Table of Contents

- Vitamin Bottles: Packaging Essentials for Supplement Brands

- Material Options for Vitamin Packaging: Plastic vs. Glass

- Design Features for Supplement Bottles That Enhance User Experience

- Compliance Requirements for Vitamin Bottles and Supplement Packaging

- Sustainable Trends in Vitamin Packaging Solutions

Vitamin Bottles: Packaging Essentials for Supplement Brands

Vitamin bottles represent the critical first line of defense in preserving supplement integrity and communicating brand value. These specialized containers are engineered to protect sensitive ingredients from environmental factors that can compromise efficacy, including light exposure, moisture, and oxygen. For supplement manufacturers, selecting the right vitamin packaging isn't merely a logistical consideration but a strategic business decision.

The global vitamin and supplement industry continues to expand, with consumers increasingly focused on preventative health measures. This growth has driven innovation in packaging solutions that balance functionality with visual appeal. Modern supplement bottles must not only preserve product quality but also stand out in competitive retail environments where shelf presence directly impacts consumer decisions.

Key Functions of Vitamin Bottles

- Protection from UV light degradation

- Moisture barrier properties

- Oxygen permeation resistance

- Tamper evidence features

- Child-resistant mechanisms

- Brand identity communication

When evaluating options for health & wellness packaging, manufacturers must consider both technical requirements and marketing objectives. The bottle becomes an extension of the product itself, conveying quality cues that influence consumer perception and trust.

Material Options for Vitamin Packaging: Plastic vs. Glass

The selection between plastic and glass vitamin bottles involves weighing various factors including product compatibility, cost efficiency, sustainability goals, and brand positioning. Each material offers distinct advantages that may align better with specific supplement formulations and target markets.

HDPE Plastic Bottles

High-density polyethylene (HDPE) remains the most common material for vitamin bottles due to its excellent moisture barrier properties and impact resistance. These bottles are lightweight, cost-effective, and highly customizable in terms of color and shape. HDPE is particularly suitable for products sensitive to moisture or those requiring extended shelf life.

PET Plastic Bottles

Polyethylene terephthalate (PET) offers exceptional clarity and good barrier properties, making it ideal for brands that want to showcase their product. PET bottles are recyclable and lightweight, reducing shipping costs while maintaining adequate protection for many supplement formulations. Their clarity allows consumers to see the product, which can enhance perceived value for certain supplement categories.

Glass Vitamin Bottles

Premium supplement brands often choose glass bottles to convey quality and purity. Glass provides superior barrier properties against oxygen permeation and chemical interactions, making it ideal for sensitive formulations or those with reactive ingredients. While heavier and more costly than plastic alternatives, glass supplement jars and bottles offer a sustainability narrative that resonates with environmentally conscious consumers.

The material selection process should consider the specific needs of the supplement formulation, including sensitivity to light, moisture, and oxygen. Brands focusing on natural or organic positioning may find that glass aligns better with their value proposition, while those prioritizing convenience and affordability might opt for plastic solutions.

Design Features for Supplement Bottles That Enhance User Experience

Beyond material selection, the design features of vitamin bottles significantly impact both functionality and consumer experience. Thoughtful design can differentiate products in crowded markets and build brand loyalty through ease of use.

Closure Systems

The closure system represents a critical component of nutraceutical packaging. Options include:

- Child-resistant caps for products requiring additional safety measures

- Flip-top caps for convenient one-handed dispensing

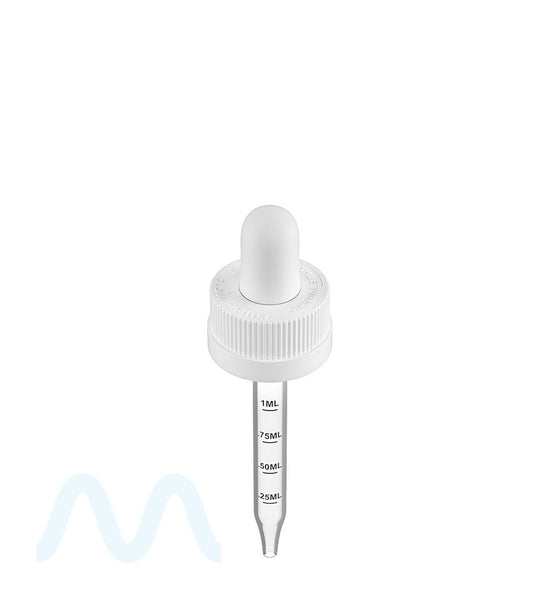

- Dispensing caps with controlled product release

- Induction-sealed liners for tamper evidence and freshness preservation

The selected closure should balance security and product protection with consumer accessibility. Difficult-to-open packages can frustrate users, particularly older adults who represent a significant demographic for vitamin products.

Bottle Shape and Ergonomics

Ergonomic considerations in bottle design can significantly enhance user experience. Features such as easy-grip contours, stable bases, and appropriately sized openings all contribute to consumer satisfaction. The bottle shape also influences shelf presence and brand recognition, with distinctive silhouettes becoming signature elements of successful supplement lines.

Label Real Estate

Vitamin bottles must accommodate comprehensive labeling requirements while maintaining visual appeal. Sufficient surface area for nutritional information, ingredient lists, dosage instructions, and marketing messages is essential. Many brands utilize expanded content labels or incorporate QR codes linking to detailed product information to maximize limited space while meeting regulatory requirements.

When designing vitamin jars and bottles, manufacturers should conduct usability testing with target demographics to ensure the packaging meets functional needs while supporting brand positioning. The most successful designs seamlessly integrate protection, compliance, and user experience.

Compliance Requirements for Vitamin Bottles and Supplement Packaging

Navigating regulatory requirements represents a significant challenge for supplement manufacturers. Vitamin bottles must comply with various regulations governing both packaging safety and information disclosure.

FDA Requirements

In the United States, the Food and Drug Administration (FDA) regulates dietary supplements under the Dietary Supplement Health and Education Act (DSHEA). While the FDA does not pre-approve supplements before they reach the market, it does mandate specific labeling requirements, including:

- The term "dietary supplement" on the label

- A Supplement Facts panel

- List of ingredients, including potential allergens

- Name and address of manufacturer or distributor

Additionally, packaging materials must be FDA-compliant for food contact, ensuring no harmful substances migrate from the packaging to the product.

Child-Resistant Packaging

Certain supplements, particularly those containing iron or other potentially harmful ingredients in large doses, require child-resistant packaging under the Poison Prevention Packaging Act. These supplement packaging solutions must meet testing protocols established by the Consumer Product Safety Commission (CPSC).

International Considerations

For brands selling globally, vitamin bottles must comply with varying international regulations. The European Union, for example, has different labeling requirements and restrictions on health claims compared to the United States. This complexity often necessitates adaptable packaging strategies or market-specific packaging variations.

Working with packaging suppliers experienced in regulatory compliance can help navigate these complex requirements. Many supplement brands opt for packaging partners who provide guidance on compliance alongside their physical packaging solutions.

Sustainable Trends in Vitamin Packaging Solutions

Sustainability has emerged as a defining factor in packaging decisions across the supplement industry. As consumers increasingly consider environmental impact in purchasing decisions, brands are exploring more sustainable options for vitamin bottles and complementary packaging.

Recycled Content

Many manufacturers now offer vitamin bottles containing post-consumer recycled (PCR) content. These options reduce virgin plastic consumption while maintaining necessary performance characteristics. PCR content percentages typically range from 30% to 100%, with higher percentages generally commanding premium prices.

Alternative Materials

Beyond traditional plastics, innovative materials are entering the vitamin packaging space, including:

- Bioplastics derived from renewable resources

- Plant-based plastics with reduced carbon footprints

- Compostable options for certain applications

While these alternatives show promise, they must still meet the functional requirements for supplement protection, including moisture and oxygen barrier properties.

Packaging Minimization

Another approach to sustainability focuses on reducing overall packaging volume. This strategy may include:

- Lighter-weight bottle designs that maintain structural integrity

- Concentrated formulations requiring smaller containers

- Refillable systems with smaller replacement packages

- Transition from bottles to vitamin pouches or supplement pouch bags for appropriate products

For products like protein supplements that require larger volumes, protein packaging innovations focus on material reduction while maintaining convenience features like easy-pour spouts.

The most effective sustainable packaging strategies align environmental benefits with consumer preferences and operational efficiencies. By communicating sustainability initiatives clearly, brands can transform their packaging choices into meaningful brand differentiators that resonate with environmentally conscious consumers.