Pet Products Packaging

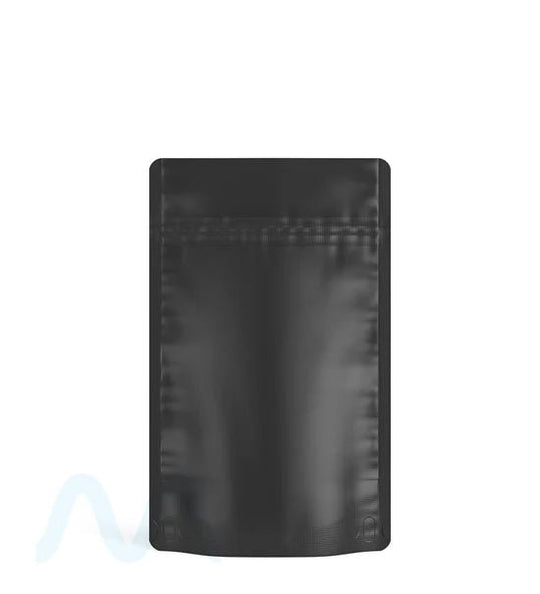

Streamline your pet product packaging with our versatile stock solutions. Featuring bottles, plastic jars, mylar bags, dropper bottles, and more, this collection is designed for secure, professional presentation at unbeatable wholesale prices.

Frequently Asked Questions About

What is PET packaging, and why is it widely used?

PET packaging refers to a type of plastic packaging that's created from polyethylene terephthalate (PET). It is widely used in various industries because it is versatile, recyclable, economical, and resistant to many chemicals.

Does PET packaging meet FDA and other regulatory standards?

Yes, PET plastic packaging has been recognized as safe for contact with food and beverages by the FDA and various regulatory agencies around the world.

Is PET better than plastic?

Yes, PET is often seen as a superior choice compared to other types of plastics since it's easier to recycle, lasts longer, and has a smaller carbon footprint.

Is PET packaging recyclable?

Yes, PET packaging products can be recycled and turned into new PET items.

Table of Contents

Pet Food Packaging Essentials: Function and Design

Pet food packaging serves as both a protective vessel and a powerful marketing tool for brands in the competitive animal nutrition market. Quality packaging must balance functionality with visual appeal while addressing the unique requirements of pet food products. From moisture barriers to resealability features, the right packaging solution can extend shelf life and maintain product freshness from manufacturing to consumer use.

When selecting pet care packaging, manufacturers must consider multiple factors including product weight, form (dry kibble, wet food, or treats), and intended shelf positioning. The packaging must protect against common degradation factors such as oxygen exposure, moisture infiltration, and pest intrusion while maintaining structural integrity throughout the distribution chain.

Modern dog food packaging often incorporates specialized barrier films, custom closures, and ergonomic design elements to enhance consumer convenience. Features like easy-pour spouts, resealable zippers, and carrying handles add value for pet owners and can significantly influence purchasing decisions at retail.

Key Functional Requirements

- Moisture and oxygen barriers to maintain freshness

- Puncture resistance for durability during shipping and handling

- Light protection to prevent nutrient degradation

- Resealable closures for extended home use

- Structural strength to support product weight

As competition in the pet food sector intensifies, packaging has evolved from purely functional containers to sophisticated marketing assets. Premium pet food brands leverage high-quality printing, unique structural designs, and tactile finishes to communicate product quality and brand positioning on crowded retail shelves.

Material Options for Pet Care Packaging

The material selection for pet care packaging directly impacts product protection, shelf life, sustainability profile, and production costs. Most commercial pet food products utilize multi-layer flexible packaging, rigid containers, or a combination of both to achieve optimal performance characteristics.

Flexible Packaging Materials

- Polyethylene (PE) - Provides moisture barrier and heat-sealability

- Polypropylene (PP) - Offers excellent clarity and moderate barrier properties

- Polyethylene terephthalate (PET) - Delivers superior oxygen barrier and printability

- Metalized films - Enhances light protection and oxygen barrier

- Paper laminates - Adds structural support and natural aesthetic

Flexible dog food bags typically combine multiple material layers to achieve the necessary protection while maintaining cost efficiency. The outer layer provides printability and durability, middle layers deliver barrier properties, and the inner food-contact layer ensures product safety and sealability.

Rigid packaging options include plastic containers, paperboard cartons, and metal cans, each offering distinct advantages for specific product types. Wet pet foods generally require hermetically sealed containers with superior oxygen barriers, while treats and supplements may perform well in simpler paperboard structures.

Custom Branding for Pet Food Bags

In the competitive pet food market, distinctive branding on packaging can significantly impact consumer perception and purchase decisions. Custom pet food packaging allows brands to communicate their unique value proposition, product benefits, and brand personality through visual design elements.

High-quality flexographic, rotogravure, and digital printing technologies enable vivid color reproduction, photorealistic imagery, and specialized finishes that enhance shelf appeal. Modern printing capabilities support detailed nutritional panels, ingredient highlights, and feeding instructions that help consumers make informed choices.

Essential Design Elements

- Brand logo and color scheme for immediate recognition

- Product photography showcasing food quality

- Pet imagery creating emotional connection

- Nutritional callouts highlighting key benefits

- Clear product weight and variety information

Custom structures further differentiate products through unique shapes, specialized closures, and innovative convenience features. Stand-up pouches, quad-seal bags, and shaped containers create distinctive shelf presence while potentially improving functionality for the end user.

Working with packaging suppliers early in the product development process allows brands to optimize both aesthetics and functionality while controlling production costs. Collaborative design approaches ensure that packaging meets marketing objectives while remaining compatible with filling equipment and distribution requirements.

Wholesale Pet Food Packaging Benefits

Sourcing wholesale pet food packaging in bulk offers significant advantages for manufacturers of all sizes. Volume purchasing reduces per-unit costs, streamlines production planning, and ensures consistent material availability for ongoing operations.

For established brands with predictable production schedules, bulk ordering minimizes administrative overhead associated with frequent purchasing cycles. Contract pricing arrangements with packaging suppliers can further stabilize costs in volatile raw material markets, providing budget predictability for extended periods.

Advantages of Bulk Purchasing

- Lower per-unit costs through volume discounts

- Reduced freight expenses with consolidated shipping

- Consistent material specifications across production runs

- Simplified inventory management

- Potential for customized specifications at scale

Even smaller manufacturers can benefit from wholesale purchasing by collaborating with flexible suppliers who offer appropriate minimum order quantities and inventory management programs. Some packaging partners provide warehousing services, allowing brands to secure volume pricing while taking physical delivery only as needed for production.

When evaluating wholesale pet food packaging suppliers, manufacturers should consider total cost of ownership rather than simply comparing unit prices. Factors such as material quality consistency, delivery reliability, technical support capabilities, and design services significantly impact the overall value proposition.

Sustainable Trends in Pet Food Packaging

Sustainability has become a critical consideration in pet food packaging development as consumers increasingly prioritize environmental responsibility. Brands are responding by implementing various strategies to reduce packaging environmental impact without compromising product protection or convenience.

Material reduction through downgauging, where film thickness is optimized to use less plastic while maintaining performance, represents one common approach. Advanced resin technologies and improved lamination processes have enabled significant material reductions in flexible packaging without sacrificing barrier properties or durability.

Renewable materials derived from plant sources are gaining traction in pet food applications. Biopolymers made from corn, sugarcane, or cellulose offer alternatives to fossil-fuel-based plastics for certain packaging components, though they often require careful evaluation for performance characteristics and cost implications.

Recyclability Innovations

- Mono-material structures designed for existing recycling streams

- Removable labels that improve package recyclability

- PCR (post-consumer recycled) content integration

- Compostable alternatives for appropriate applications

- Consumer education regarding proper disposal

Beyond materials, sustainable packaging strategies include optimization of package-to-product ratios, improved palletization efficiency to reduce transportation impacts, and packaging designs that minimize food waste through better preservation and portion control.

As the pet food industry continues evolving, packaging sustainability will remain a significant focus area, with ongoing innovations addressing both consumer expectations and environmental imperatives. Brands that proactively develop more sustainable packaging solutions can create meaningful differentiation while contributing to broader environmental goals.