CGSC-21.5OZXL-OWH

/

CGSC-21.5OZXL-OBK

/

CGSC-21.5OZXL-WHT

/

CGSC-21.5OZXL-BLK

/

CGSC-18.5OZXL-WHT

/

CGSC-18.5OZXL-OWH

/

CGSC-18.5OZXL-OBK

/

CGSC-18.5OZXL-BLK

/

CHUBBY GORILLA | Child Resistant White Plastic Spiral XL Jar w/ White Cap | 92.5mm - 10oz - 80 Count

CGSC-10OZXL-WHT

/

CHUBBY GORILLA | Child Resistant Clear Plastic Spiral XL Jar w/ White Cap | 92.5mm - 10oz - 80 Count

CGSC-10OZXL-OWH

/

CHUBBY GORILLA | Child Resistant Clear Plastic Spiral XL Jar w/ Black Cap | 92.5mm - 10oz - 80 Count

CGSC-10OZXL-OBK

/

CHUBBY GORILLA | Child Resistant Black Plastic Spiral XL Jar w/ Black Cap | 92.5mm - 10oz - 80 Count

CGSC-10OZXL-BLK

/

CGABB-500ML-WHT

/

CGABB-500ML-BLK

/

CGABB-250ML-WHT

/

CGABB-250ML-BLK

/

CGABB-1LTR-WHT

/

CGABB-1LTR-BLK

/

CGRCR5ML-WTA

/

JCR5-PILLOW-BWJ

/

JCR5-PILLOW-WWJ

/

EBWMCGJ2F-180

/

GDCRRECT30-BK

/

EBWMCGJ2-160

/

.

.

Table of Contents

Sauce Bottles for Commercial Food Production

Sauce bottles represent a critical packaging component for food producers looking to deliver consistent quality while maintaining product freshness. Whether you're bottling hot sauce, salad dressing, marinade, or specialty condiments, the right container impacts everything from shelf life to consumer experience. Quality sauce bottles protect flavor profiles, prevent contamination, and communicate brand values through visual and tactile elements.

For commercial kitchens and food manufacturers, selecting appropriate bottles for sauces involves balancing functionality, aesthetic appeal, and cost efficiency. The container must withstand filling temperatures, provide reliable sealing mechanisms, and facilitate easy dispensing for end users. As production scales, sourcing empty sauce bottles in bulk becomes a strategic decision that affects operational efficiency and product consistency.

Material Options for Bottles for Sauces

When selecting sauce bottles, material choice significantly impacts product preservation, consumer perception, and environmental footprint. Each material offers distinct advantages depending on the sauce type and intended use case.

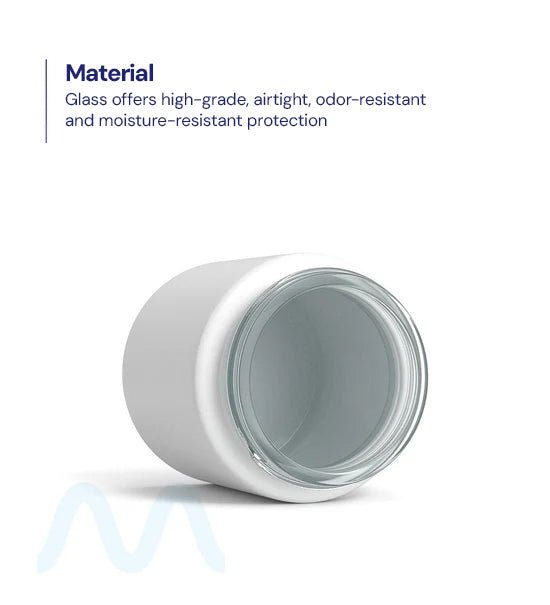

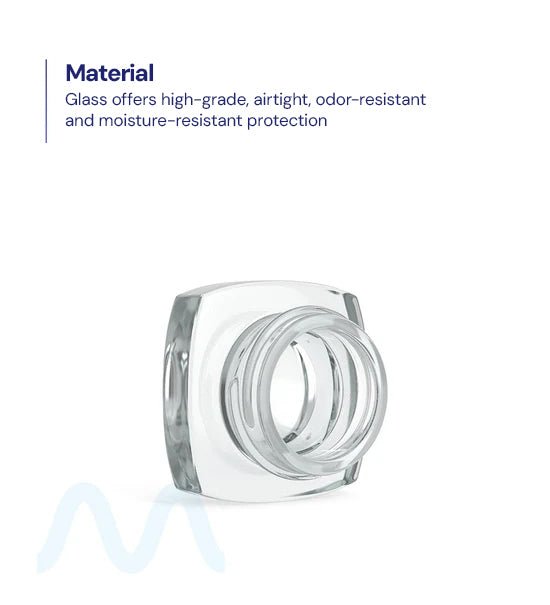

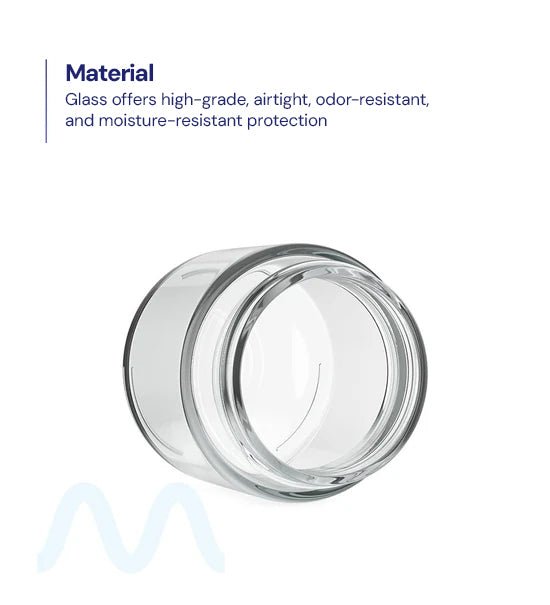

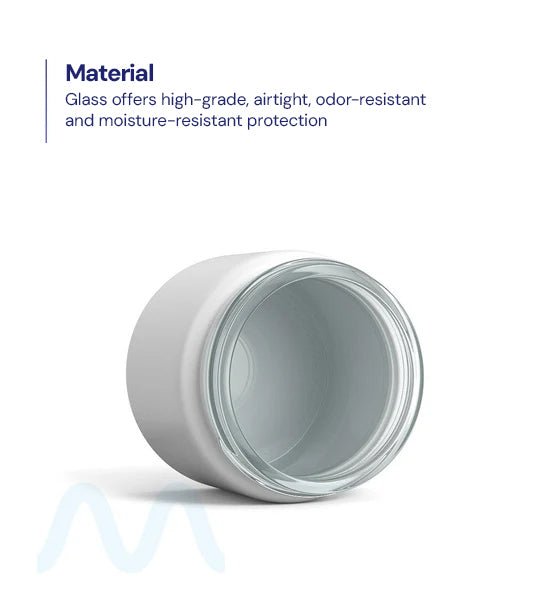

Glass Sauce Bottles

Glass remains the premium choice for many sauce manufacturers due to its inert properties and quality perception. Sauce jars made from glass offer excellent barrier protection against oxygen and moisture while preserving flavor profiles without chemical interaction. Clear glass allows consumers to see the product, which can be particularly appealing for colorful or artisanal sauces.

Similar to food jars, glass sauce bottles can withstand hot-filling processes and maintain structural integrity during pasteurization. However, they present higher shipping weights and potential breakage concerns compared to plastic alternatives.

Plastic Sauce Bottles

Plastic options dominate the squeeze bottles for sauce category, offering flexibility, lightweight properties, and reduced breakage risk. High-density polyethylene (HDPE) and polyethylene terephthalate (PET) are commonly used for sauce packaging due to their food-safe properties and durability.

Plastic bottles typically feature in food containers lineups and provide cost advantages for high-volume production runs. They're particularly suitable for products requiring frequent dispensing or targeted application, such as condiments and cooking sauces.

Selecting the Right Sauce Bottle Sizes

Sauce bottle sizing should align with both consumer usage patterns and operational efficiency goals. Standard sizing helps streamline production while meeting market expectations for particular sauce categories.

Common Sauce Bottle Capacities

- 2-5 oz bottles: Ideal for premium hot sauces, sample sizes, or travel portions

- 8-12 oz bottles: Standard for everyday condiments and cooking sauces

- 16-32 oz bottles: Popular for dressings, marinades, and food service applications

- 64 oz and larger: Primarily for commercial kitchen use or bulk retail

When planning production runs, consider how bottle dimensions affect filling line efficiency, case packing, and shelf space utilization. Standardizing on compatible bottle families can reduce changeover times and simplify inventory management.

Many producers develop packaging systems similar to other food categories like honey jars or spice jars, creating visual consistency across product lines while optimizing operational processes.

Functional Features in Squeeze Bottles for Sauce

Functionality drives consumer satisfaction with sauce packaging, particularly for products used frequently during food preparation or at the table. Key features to consider include closure systems, dispensing mechanisms, and ergonomic design elements.

Closure and Dispensing Options

- Flip-top caps: Provide controlled dispensing and one-handed operation

- Twist caps: Offer secure sealing for products with longer use cycles

- Reducer caps: Control flow rates for thin liquids like hot sauce

- Pump dispensers: Deliver measured amounts of thicker sauces and dressings

- Shrink bands: Add tamper evidence and preserve freshness

The viscosity of your sauce product should guide dispensing mechanism selection. Thicker products like mayo or aioli benefit from wide-mouth squeeze bottles, while thinner vinaigrettes may require flow restrictors to prevent over-dispensing.

Consider how your packaging interacts with different usage environments. Restaurant applications might prioritize durability and precise dispensing, while retail products may focus more on shelf appeal and consumer convenience features.

For specialty applications, custom solutions can be developed similar to those used for gummy packaging or stevia packaging, where unique dispensing requirements drive container design.

Sourcing Wholesale Sauce Bottles Efficiently

Purchasing sauce bottles in bulk offers significant cost advantages but requires strategic planning to maximize value. Effective wholesale sourcing balances price considerations with quality assurance, delivery reliability, and minimum order requirements.

When evaluating wholesale sauce bottles suppliers, consider these factors:

- Minimum order quantities and volume price breaks

- Consistency of materials and dimensions across production runs

- Compatibility with your filling equipment and closure systems

- Lead times and inventory management requirements

- Customization options and associated costs

- Regulatory compliance documentation

Many suppliers offer complementary packaging components alongside bottles, creating opportunities to consolidate ordering across multiple product lines. For instance, businesses that need sauce bottles might also require canning jars or food bags for other products in their lineup.

For specialty food producers, aligning packaging strategies across product categories can strengthen brand recognition and streamline operations. Companies producing sauces might also package complementary products in pickling jars or coffee bags with consistent design elements.

When sourcing empty sauce bottles, consider both immediate needs and future scalability. Starting with standard stock options allows for testing market response before investing in custom molds or decorative features. As volumes increase, custom branding options become more economically viable and can significantly enhance shelf presence.

Sustainable packaging considerations are increasingly important to consumers. Evaluate suppliers based on their ability to provide eco-friendly options such as recycled content plastics, lightweight glass formulations, or innovative materials that reduce environmental impact while maintaining product protection.

Ultimately, building strong supplier relationships for wholesale sauce bottles creates a competitive advantage through improved reliability, consistent quality, and potential for collaborative innovation as your product line evolves.